Hot Work Tool Steels

1.2365 Standards DIN X32CrMoV3-3

Chemical Composition

Applications

Used as a piston in the injection of copper and alloys

Heat Treatment Properties

- Stress Relief °C

650 - Soft Annealing °C

780-810 - Delivery Hardness

+A / max. 229

Hardness

- Austenitizing °C

1010-1050 - Cooling

Oil, Fluid bed , Air

Hardness After Hardening

- HRC

51

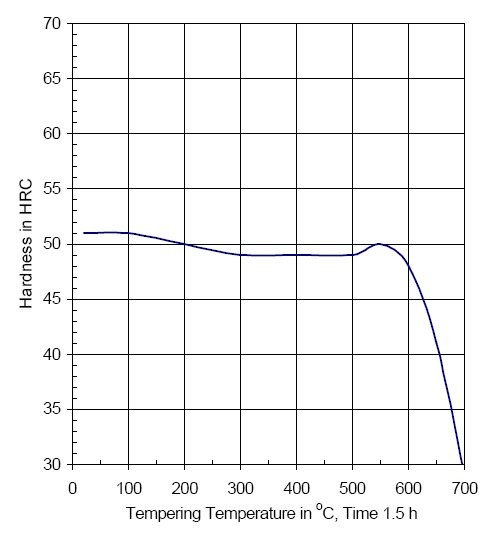

| Tempering °C | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 51 | 50 | 49 | 49 | 49 | 50 | 48 | 41 | 29 |

| Tensile Strenght N/mm2 | 1730 | 1680 | 1620 | 1620 | 1620 | 1680 | 1570 | 1300 | 940 |

Other Hot Work Tool Steels

Contact Us

You can call or email us for all our new generation high performance steels.

Online Catalog

You can download our catalog that contains material information about Birleşik Metal steels here.